Auger Torque announce the addition of Kinshofer Hydraulic KSB Hammers

Cheltenham, December 2019 – Auger Torque, the leading manufacturer and global provider of earth-moving attachments has today announced the addition of the Kinshofer range of KSB Hammers to their product portfolio.

There are 8 models in the KSB range, catering for machines from 500kg up to 12T in operating weight with more models on the horizon. Being a gas-type-breaker, these units are able to tolerate high back pressure and are independent of oil temperatures, meaning the KSB series has a wide range of calibration when it comes to oil flow and will allow operators to use the hammer on a multitude of host-machines giving enhanced versatility to the operator.

The Hammers are made of high-grade steel and consist of a simple, ingenious design with only two moving parts. It uses a cartridge design without tie rods and are therefore extremely quiet, allowing operators to work longer hours and complete contracts in shorter time frames. A comprehensive immersion-hardened range of chisels are available, enabling use on a variety of materials from reinforced concrete, layered rock, highly compacted rock to special tools for wood cutting, pile driving and even asphalt cutting.

Matt Hencher, Global Operations Manager, Auger Torque Group states “What sets this range of hammers apart from other gas-type breakers is the use of a high grade “Freudenberg” three lip seal – giving the user constant power output over a longer period of time, and up to 30% higher performance than oil type breakers.

The special seal gives more performance and reduces the need for nitrogen refills to a minimum, providing up to 300% higher gas tightness compared to standard seals, resulting in a simple, efficient and cost effective breaker with less downtime and less money spent on refills” Matt Hencher goes on to say “The hydraulic connections are completely encased in the body of the hammer, enabling operation in tight access situations common, without having to worry about damaging the hydraulic hoses and the dust seal on the upper bushing of course comes as standard”.

For press enquiries please contact:

Jo Collins, Head of Group Marketing

M: +44 (0) 773 883 9677

T: +44 (0) 1451 861 652

E: jo.collins@augertorque.com

Erdbohrer

Erdbohrer  Bohrschnecken & Verlängerungen

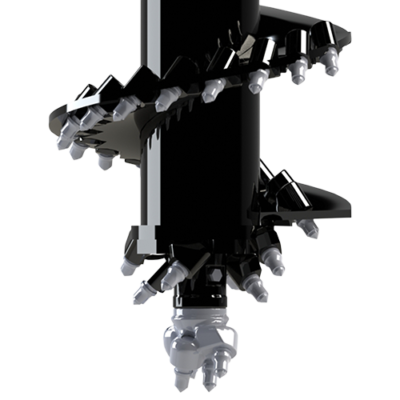

Bohrschnecken & Verlängerungen  Schraubanker-Antriebe

Schraubanker-Antriebe  Hard Rock Schnecke

Hard Rock Schnecke  KSB-Hammersortiment

KSB-Hammersortiment  Grabenfräsen

Grabenfräsen  Variable Mulcher

Variable Mulcher  Heckenschere

Heckenschere  Kegelbrecher-Eimer

Kegelbrecher-Eimer  Trommelschneider

Trommelschneider  Holzspalter

Holzspalter  Baumstumpf-Fräsbohrer

Baumstumpf-Fräsbohrer  Betonmischtrommeln

Betonmischtrommeln  Palettengabeln

Palettengabeln  Kehrschaufel

Kehrschaufel  In-Site Produktpalette

In-Site Produktpalette